Attainable Regions for Maleic Anhydride Manufacture in a Plug-Flow Reactor

Attainable Regions for Maleic Anhydride Manufacture in a Plug-Flow Reactor

The synthesis of maleic anhydride, , involves the following reactions in the presence of a vanadium pentoxide catalyst:

C

4

H

2

O

3

C

6

H

6

9

2

O

2

C

4

H

2

O

3

CO

2

H

2

C

4

H

2

O

3

O

2

CO

2

H

2

C

6

H

6

15

2

O

2

CO

2

H

2

If air is supplied in excess, the concentration of oxygen can be considered as constant and the reaction rates are given by =, =, and =, where is the rate constant of reaction (expressed in kg catalyst), is the concentration of benzene, and is the concentration of maleic anhydride.

r

1

k

1

C

A

r

2

k

2

C

P

r

3

k

3

C

A

k

i

i

3

m

-1

s

C

A

C

P

The temperature-dependent rate constants are given by =4280, =70100, and =26.

k

1

-12660

T

e

k

2

-15000

T

e

k

3

-10800

T

e

The governing equations at steady-state, obtained by writing molar balances, for a packed-bed reactor modelled as a PFR (plug-flow reactor) are

v

0

d

C

A

dW

k

1

C

A

k

3

C

A

C

A

3

m

v

0

d

C

P

dW

k

1

C

A

k

2

C

P

C

P

v

0

3

m

W

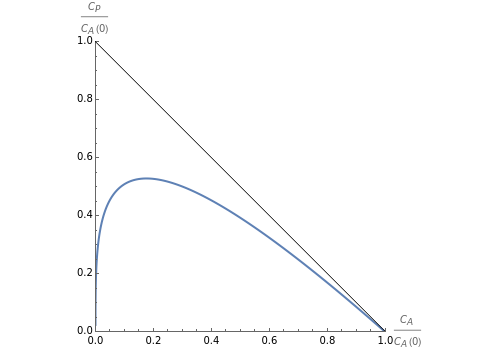

The final/outlet concentrations of benzene ) and maleic anhydride ) are obtained by solving the steady-state equations numerically, with the weight of the catalyst ranging from 0 to 10,000 kg.

(

C

A

(

C

P

This Demonstration plots the attainable region for maleic anhydride synthesis for values of the temperature fixed by the user.