Startup and Steady State in a Chemostat

Startup and Steady State in a Chemostat

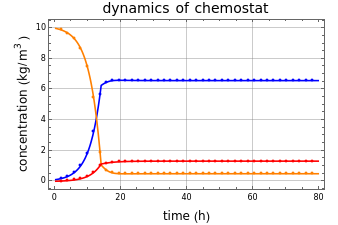

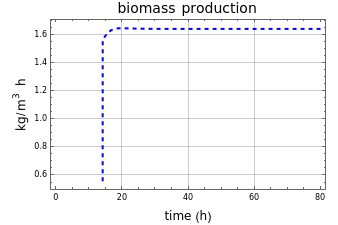

This Demonstration shows the operation of a chemostat. Starting up as a batch reactor, the concentrations change with time. After this short transient period, the bioreactor settles into a steady state.

The behavior of a chemostat, also called a continuous reactor, can be characterized by the concentration profiles of the reactants and products.

In this Demonstration, is time, is the concentration of a reactant consumed (also called the substrate), is the biomass (or cell) concentration, is the concentration of a product and is the dilution rate. The concentration in a perfectly mixed tank is uniform throughout the vessel and is therefore identical to the concentration of the effluent stream.

t

S

X

P

D

Details

Details

The characteristics of continuous operation are as follows:

Snapshot 1: steady state; after an initial startup period, there is no variation of concentrations with time

Snapshot 2: constant reaction rates, where is the biomass reaction rate, is the reaction rate of the consumed reactant and is the product reaction rate

r

X

r

S

r

P

Snapshot 3: Washout of the organisms (cells) will occur when the dilution rate is greater than the specific growth rate . This corresponds to the complete removal of cells by flow out of the tank. In many references, including[1], the variables , , and productivity are plotted versus the dilution rate , which characterizes the steady state in a chemostat. See Related Links.

D

μ

X

S

P

DX

D

Some suggestions for the user:

Increase interactively to note effect on washout.

D

Change the feed substrate concentration to alter the steady state.

S

F

Investigate the influence of maintenance requirements on the steady-state biomass concentration.

Operate initially as a batch reactor with , and switch to chemostat operation with . is the maximum specific growth rate, and in this case was set up to .

D=0

D<

μ

max

μ

max

0.3

-1

h

Calculate , the biomass-substrate yield, making use of the yield graph.

Y

XS

References

References

[1] I. J. Dunn, E. Heinzle, J. Ingham and J. E. Přenosil, Biological Reaction Engineering: Dynamic Modelling Fundamentals with Simulation Examples, Second Edition, Weinheim, Germany: Wiley-VCH, 2003.

External Links

External Links

Permanent Citation

Permanent Citation

R. Ricardo Sánchez

"Startup and Steady State in a Chemostat"

http://demonstrations.wolfram.com/StartupAndSteadyStateInAChemostat/

Wolfram Demonstrations Project

Published: August 4, 2021