Volatility Inversion in Extractive Distillation

Volatility Inversion in Extractive Distillation

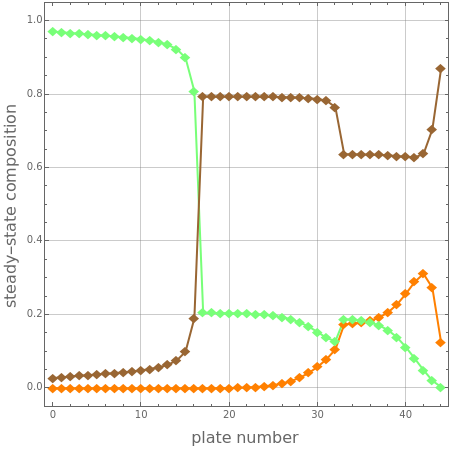

Consider an extractive distillation column operating at atmospheric pressure with 43 stages, a partial reboiler, and a total condenser. It is used to separate acetone and methanol using chlorobenzene as an entrainer.

Pure entrainer at is fed to the column at a flow rate, , to be set by the user at stage 17 (counting from the top). The lower feed is composed of an equimolar mixture of acetone and methanol. The lower feed, at , is located at stage 33 (counting from the top) and has a flow rate equal to .

320K

FU

320K

540kmole/hr

The Demonstration solves the MESH equations (mass,equilibrium, summation, and heat) and displays the composition and temperature profiles for user-set values of the reflux ratio, . The second degree of freedom is set by taking a distillate flow rate equal to .

RR

270kmole/hr

For this particular entrainer selection, one observes a phenomenon called volatility inversion. Indeed, methanol (b.p. ) exits the extractive distillation column as a pure distillate product, while the more volatile component acetone (b.p. ) leaves accompanied by the entrainer (i.e., chlorobenzene) at the bottom of the column.

64.65°C

56.05°C

Details

Details

The mixture is assumed to obey modified Raoult's law, and activity coefficients are predicted using the Wilson model.

References

References

[1] M. F. Doherty and M. F. Malone, Conceptual Design of Distillation Systems, Boston: McGraw-Hill, 2001.

[2] E. J. Henley and J. D. Seader, Equilibrium-Stage Separation Operations in Chemical Engineering, New York: Wiley, 1981.

[3] W. L. Luyben and I.-L. Chien, Design and Control of Distillation Systems for Separating Azeotropes, Hoboken, NJ: Wiley, 2010.

Permanent Citation

Permanent Citation

Housam Binous, Naim Faqir

"Volatility Inversion in Extractive Distillation"

http://demonstrations.wolfram.com/VolatilityInversionInExtractiveDistillation/

Wolfram Demonstrations Project

Published: July 18, 2012